Portfolio

PLC control panel design and build

PLC control is our forte. With a strong E&I background, our solutions are durable and are built with finesse.Supervisory Control and Data Acquisition

UX/User Experience is the core of our HMI and SCADA workflow, The screen visualisation and navigation must be intuitive, so to reach this, we like to involve the end-user operators at design time. Functionality, maintainability, and future expansion are key to our delivery.With the emergence of IoT, the role of UX is playing a wider role as we need to make our UIs'/User Interfaces easier to follow and navigable over the web. In some cases, financial and managerial staff need to visualise performance so a complicated HMI is unusable. Gone are the days when a computer specialist decides on how a machine interface should look. The reality is that a typical hard-core programmer thinks differently to a machine or plant operator. Making a system difficult to navigate means longer learning curves and increased downtime, costing you money.

HMI

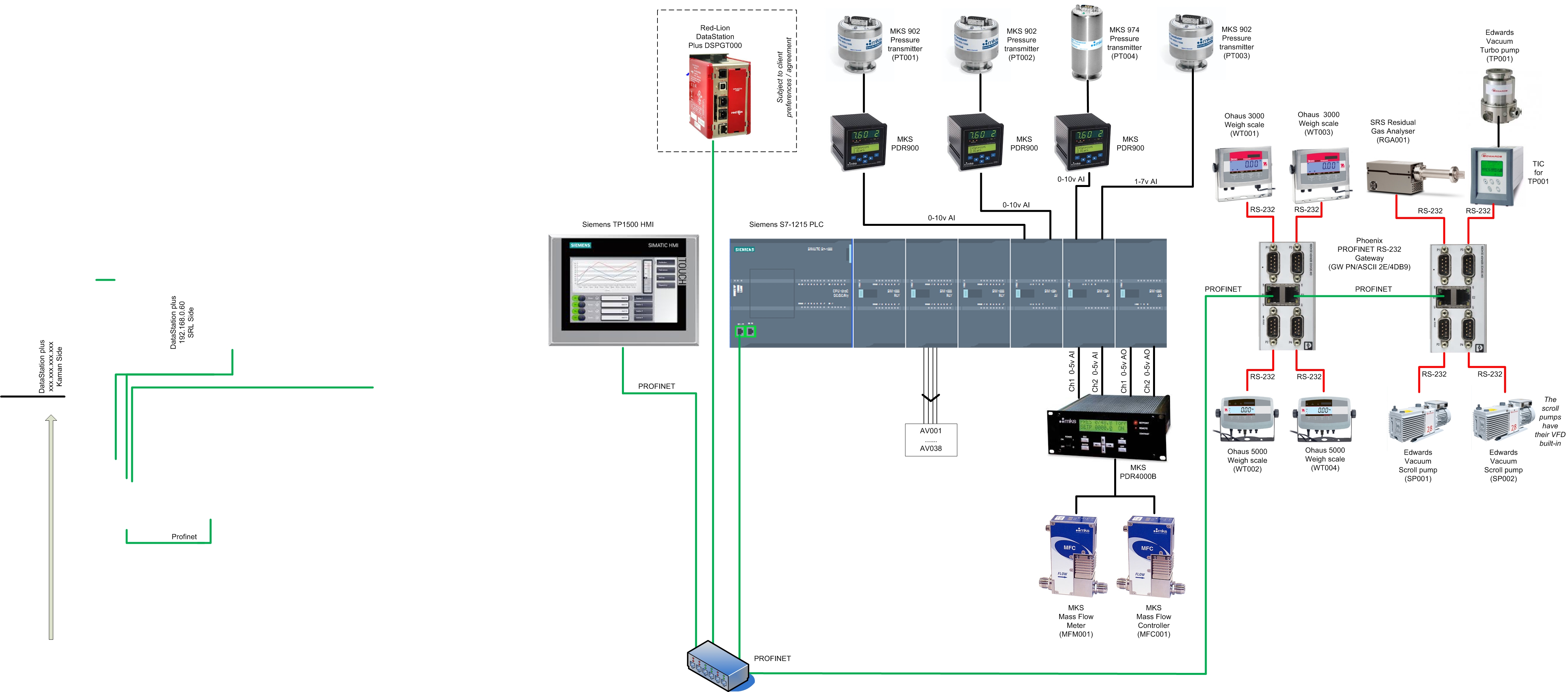

Tank pH, temperature, and level automatic controls with dual validation, as part of a larger manufacturing plant which is also fully automated by Control System Integration Ltd.Architecture

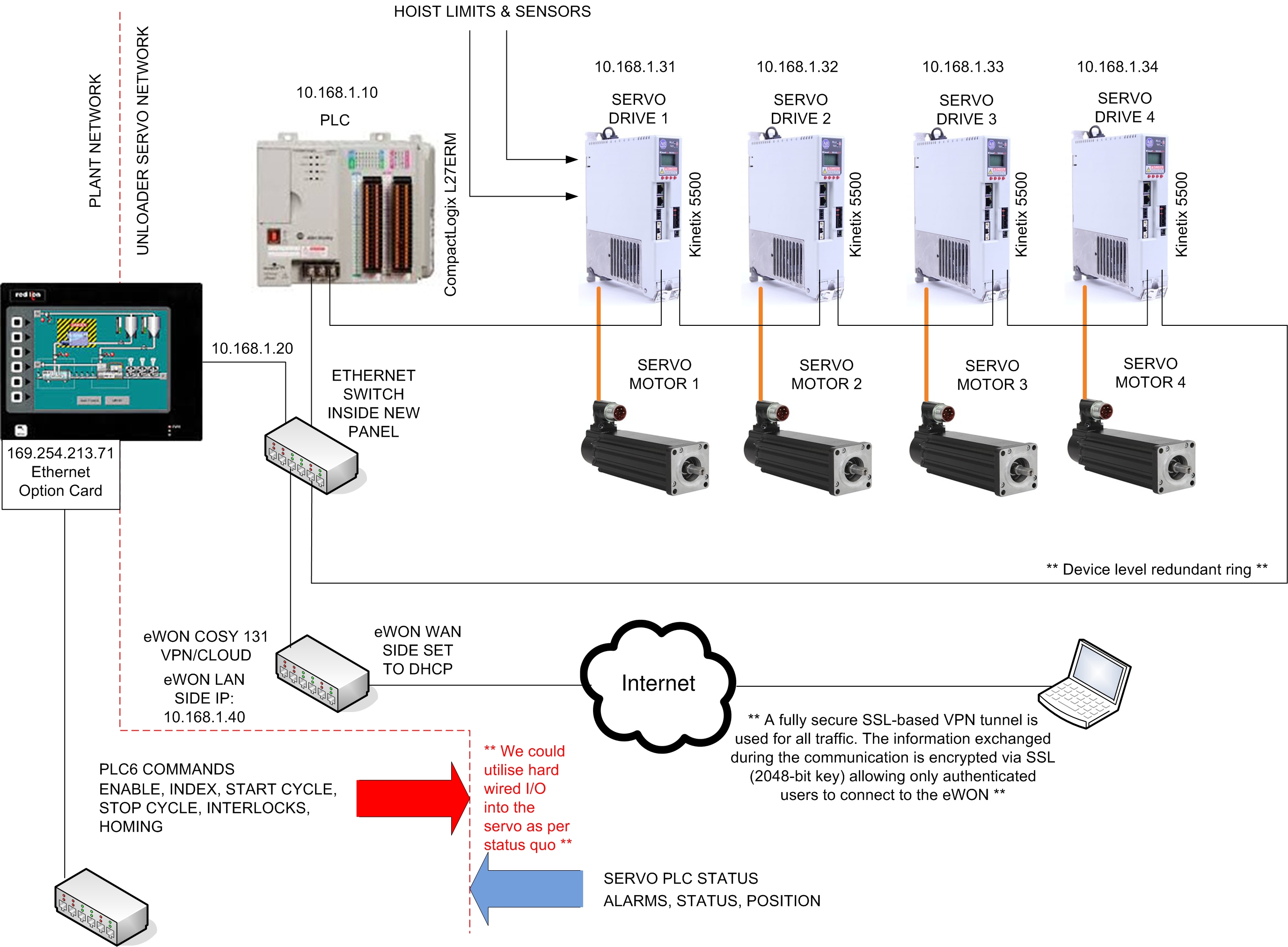

A great architectural design helps all team members visualise the challenge and the solution, it provides a vehicle for people to add their comments at an early stage. An informative architecture is at the backbone of our design. The architecture forms part of a great documentation system too so that others can follow. HMI/SCADA permitting, this information is placed on the user interface.HMI Development for a complex CNC machine

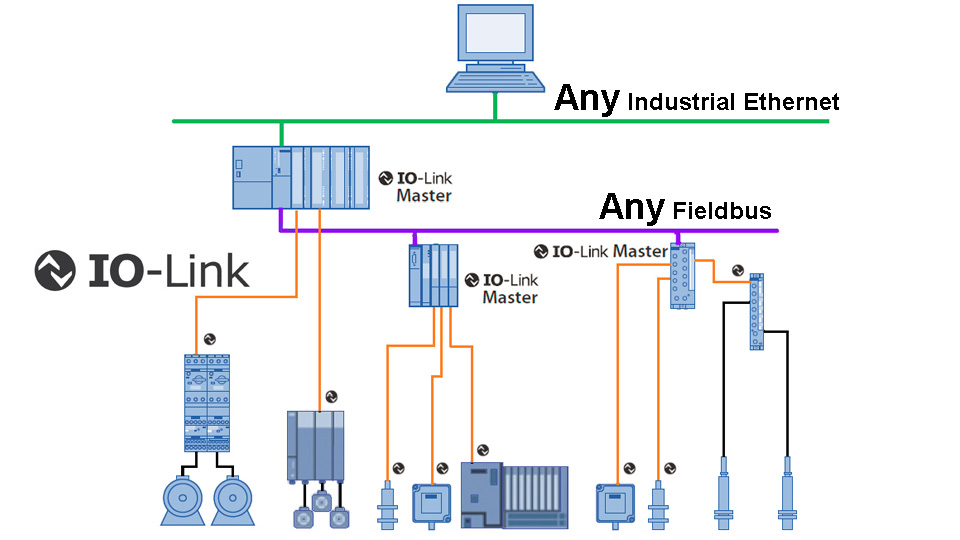

Regardless of the machine's complexity, we will create a practical solution and where possible, make the user interface easy to navigate.Any Fieldbus! IO-Link is here to stay at the sensor/actuator layer

We always recommend IO-Link. Above the sensor/actuator level we can work with Profinet, Modbus TCP, Profibus, CC-Link-IE, Ethernet/IP, ControlNet, or Ethercat. We are certified engineers for Profibus and Profinet and have many years of experience in Fieldbus. Each has its pros and cons, depending on the architecture, newness of the hardware, and CPU/net interface. Where we stand out is that we are strong in all Fieldbus networks so we can give you an impartial opinion for your solution. Many of the new sensors on the market are already equipped with IO-Link so integration is almost inevitable at some stage in the future.By the way, IO-Link is a great way to get low-level signals and sensor signatures up to the Cloud! This is bliss from a maintenance and asset management point of view! "The growth of the global IO-link market size is anticipated to driven by factors such as the ability to support much higher level Fieldbus and Ethernet communication protocols, surge in demand for Industry 4.0, and rise in government initiatives toward the adoption of industrial automation drive the IO-link market growth."

[Source: www.alliedmarketresearch.com]

VFD/Inverter design

With over 300 VFD/Inverters commissioned to date, using most brands, over most industries, you can be sure that your drive system will be delivered and commissioned right. This means your downtime is reduced while commissioning. This also means your drives panel is fit for purpose and built to last.Many general engineers are unaware of the behaviors of the different drive types and they can choose a drive based on price but it may not suit the application. For example, a variable torque/constant power drive is unsuitable for a constant torque application. This error will hamper your project, and you'll end up buying the drive again.

We are actually developing a specialist drive for new product development.

Please contact us to remedy your drive concerns. This call could save you money.